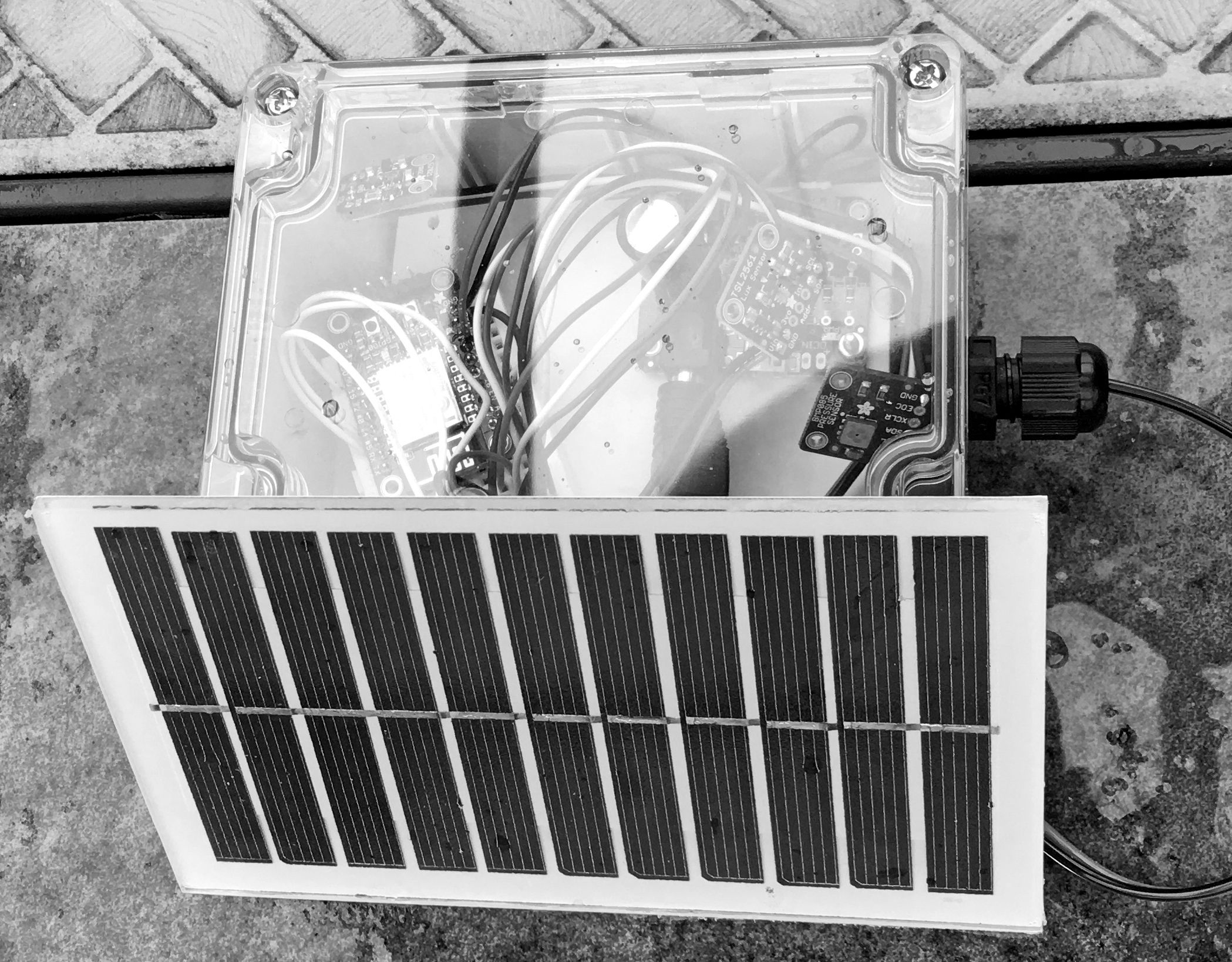

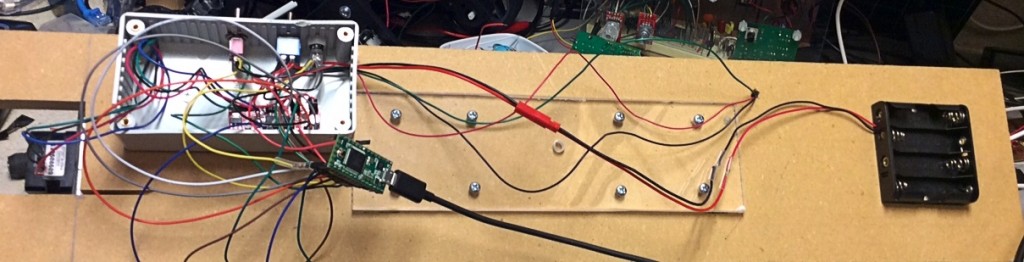

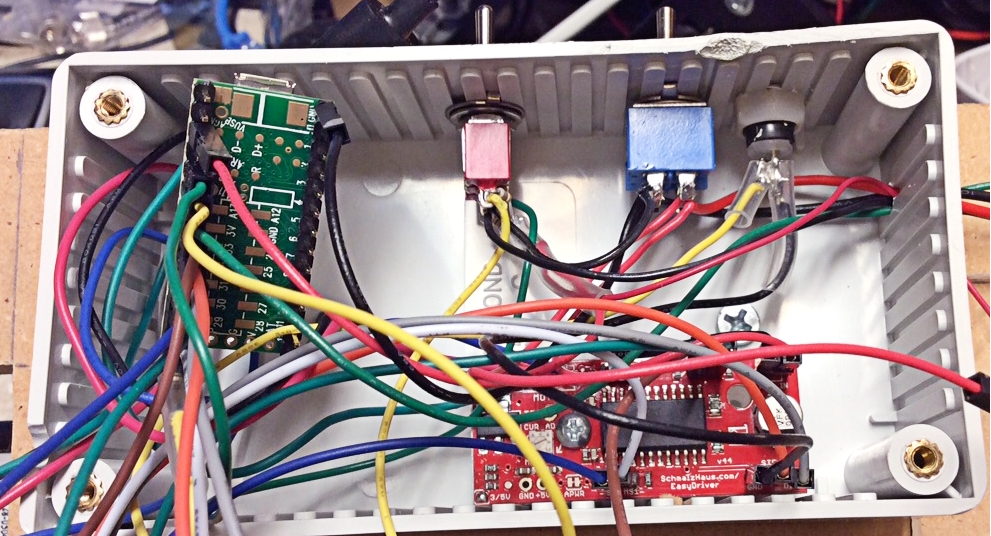

For a while I’ve wanted a system that can report weather data and be solar powered. The ESP8266 is an cheap choice, and this is my first experience using Blynk. The prototype was a weekend project that just needed some assembly. It’s entirely built from Adafruit modules. The EPS8266 is put into deep sleep for 60 seconds…even that may be too frequent. The downside of using the EPS8266 deep sleep mode with Blynk: Blynk often reports the device as offline. I think this is because it can’t do a pull. The EPS8266 wakes up, pushes data, then goes back to sleep.

All the sensors are I2C based. The standard Arduino libraries work right out of the box. If the prototype works well, I might create a pcb that glues everything together.

I’m using the following Adafruit boards:

- BMP086 pressure sensor

- TSL2561 lux sensor

- si7021 RH sensor

- ESP8266 Huzzah

- Solar Lion charger #390