I started playing around with the idea of using an Arduino based water pressure controller because of fears of the common and ubiquitous Square D pressure switch failing. There are many accounts of how these switches fail after only a few years. If you are switching DC voltages, then they fail faster.

The primary goal of this project:

- Use a variable pressure sensor, not a switch with a longer lifetime

- Provide over heating protection via a remote temperature sensor

- Use a float switch to detect when the resevoir tank is empty

I’ve started making some headway on this. I have an LCD displaying status, and I picked up two Sensata 67CP sensors on ebay. These Sensata sensors are probably for a hydraulic application, my friend John thinks. The smaller threading is 5/16-24. I purchased a brass PEX end cap, drilled, and tapped it for this sensor. The output at 0psi (sea level) hovers about 1.3 volts and a regression curve shows it to be linear to about 60psi.

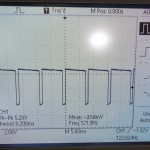

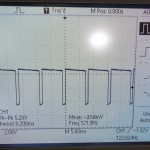

I have a DC Fotek SSR that I’m using for pump control. I’m driving the SSR from a PWM port on timer1. I’ve changed the prescalar constant to something lower that the Fotek can cleanly switch. I found out the hard way that using a digital port on timer0 messes up the serial output to the LCD.